Cogged Belt

Welcome to Umar Farooq Belting – Your Premier Destination for High-Performance Cogged Belts, Offering Precision and Reliability!

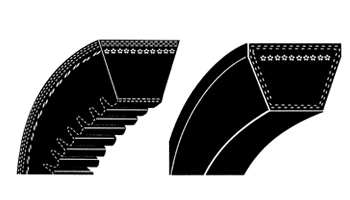

A COG belt is a belt with teeth. That is instead of a smooth belt, such as a simple v-belt, that will always have some slip, and whose drive ratio is then only a close approximate ratio, a “COGGED” belt has teeth, so that the drive ratio is an exact value based on the number of teeth in each pulley (or sprocket) that the belt passes over.

Toothed belts also permit much higher torque to be driven than not toothed belts.

So, the COG number of a pulley is the number of teeth in the pulley.

Umar Farooq Belting takes pride in presenting a diverse and premium range of Cogged Belts, designed to meet the rigorous demands of modern industries. Our dedication to excellence and commitment to quality make us a trusted source for superior cogged belt solutions. Explore the various types of cogged belts we offer, each meticulously engineered to deliver optimal performance in specific applications.

Types of Cogged Belts:

- Classical Cogged Belts:

- Features: Our classical cogged belts combine the advantages of a classical V belt with the improved flexibility and efficiency provided by cogs. Ideal for a wide range of industrial applications, these belts offer reliable power transmission.

- Raw Edge Cogged Belts:

- Features: Raw edge cogged belts are designed for enhanced flexibility and efficiency. The absence of fabric on the belt’s edges reduces bending stress, making them suitable for high-speed and high-torque applications.

- Double-Sided Cogged Belts:

- Features: Double-sided cogged belts offer bidirectional power transmission with cogs on both sides. This design provides increased flexibility and allows for reverse bending, making them versatile for various industrial applications.

- Metric Cogged Belts:

- Features: Metric cogged belts adhere to international standards, ensuring precise dimensions and compatibility. These belts are widely used in machinery and automotive applications where metric measurements are preferred.

- Ribbed Cogged Belts:

- Features: Ribbed cogged belts combine the advantages of ribbed belts with the enhanced efficiency of cogs. They are ideal for applications where a combination of flexibility and high power transmission is required.

Why Choose Umar Farooq Belting for Cogged Belts:

- Premium Quality: Umar Farooq Belting is committed to providing cogged belts of the highest quality. Our belts undergo rigorous testing to ensure durability, reliability, and optimal performance.

- Application Expertise: With a deep understanding of industrial needs, our team offers expert guidance to help you select the right type of cogged belt for your specific application, ensuring efficient power transmission.

- Custom Solutions: We recognize that different industries have unique requirements. Umar Farooq Belting provides custom solutions, tailoring our cogged belts to meet the specific needs of your machinery and applications.

- Comprehensive Range: Our diverse range of cogged belts caters to a wide array of industrial applications. Whether you require classical, raw edge, double-sided, metric, or ribbed cogged belts, Umar Farooq Belting has the solution for you.

Elevate your industrial processes with Umar Farooq Belting’s premium cogged belts. Whether you need classical reliability, raw edge efficiency, or metric precision, our cogged belt solutions are designed to exceed your expectations. Choose Umar Farooq Belting for superior quality, performance, and durability in cogged belts!